Carbon Fiber Plate/Strip

Carbon fiber plates/strips are typically made by

pressing multiple layers of carbon fiber fabric or unidirectional carbon fiber

together under high pressure and temperature, processing with a high-strength

epoxy resin. Carbon fiber plates are increasingly being applied to

constructions as a strengthening material due to their high strength-to-weight

ratio, excellent stiffness, and durability. They are typically used to

reinforce structures such as concrete, masonry, or steel that require

additional support to withstand heavy loads, seismic forces, or other stresses.

Characteristics:

1. Short construction period

2. No maintenance required

3. Easy installation, low

installation cost

4. Light weight, no influence to

original structure

5. Corrosion resistance, long-term

effect of 50 years

6. Cost effective compared with

other retrofitting method

7. 1 layer of CFRP laminate is

equivalent to 4-8 layers of CFRP fabric

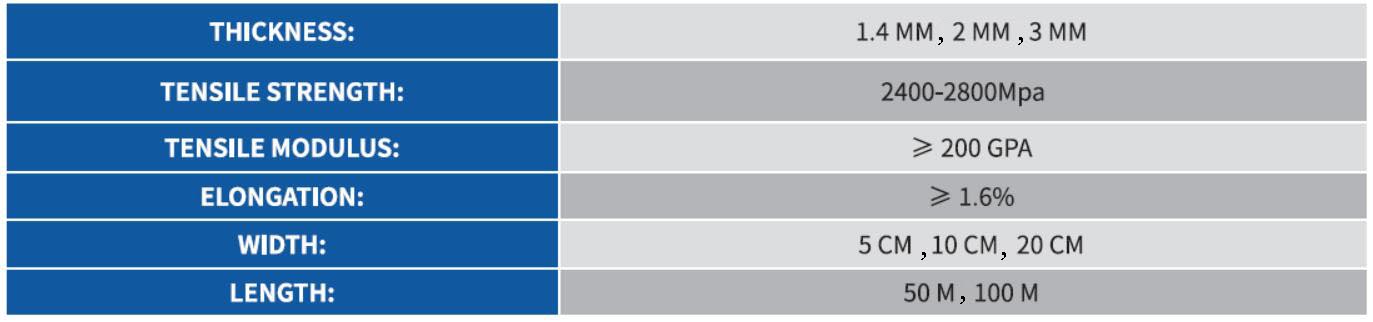

Technical Data:

Applications:

In concrete structures, carbon fiber plates are commonly used to increase the flexural strength, shear strength and stiffness of beams, columns and slabs. In masonry structures, carbon fiber plates are used to reinforce walls and improve their resistance to seismic and wind loads. In steel structures, carbon fiber plates can be used to reinforce steel members and increase their load-carrying capacity. They can be anchored to the surface of the steel using mechanical fasteners, adhesive anchors, or a combination of both.